Sleipner Steel Data Sheet

This combination means that uddeholm sleipner is an extremely versatile conventional tool steel for medium run cold work tooling.

Sleipner steel data sheet. Cold work steel assab 88 sleipner is a chromium molybdenum vanadium alloyed tool steel which is characterized by. Used by lionsteel in their folders. Good wear resistance good chipping resistance high compressive strength high hardness 60hrc after high temperature tempering. In east south east asian countries served by assab uddeholm.

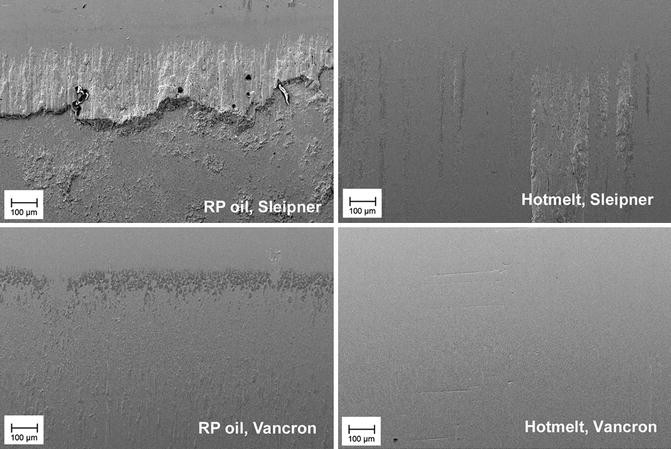

21 60 6 x 30 x 1000 mm. High strength steel sheet materials now being used for automotive parts. Uddeholm sleipner is a chromium molyb denum vanadium alloyed tool steel which is characterised by. Physical data hardened and tempered to 62 hrc.

Uddeholm sleipner is a high alloyed tool steel with a very broad property profile. 37 00 6 x 40 x 1000 mm. Modification of the classic aisi d2 tool steel. Sleipner bohler uddeholm uddeholm proprietary cold work tool steel.

It is also a very good steel for all types of surface treatments. Sleipner offers many of the advantages as a high hardness tool steel like d2 while offering a much more stable edge. Uddeholm sleipner is a chromium molyb denum vanadium alloyed tool steel which is characterised by. Good wear resistance good chipping resistance high compressive strength high hardness 60 hrc after high temperature tempering good through hardening properties good stability in hardening good resistance to tempering back good wedm properties good machinability and grindability good surface treatment properties.

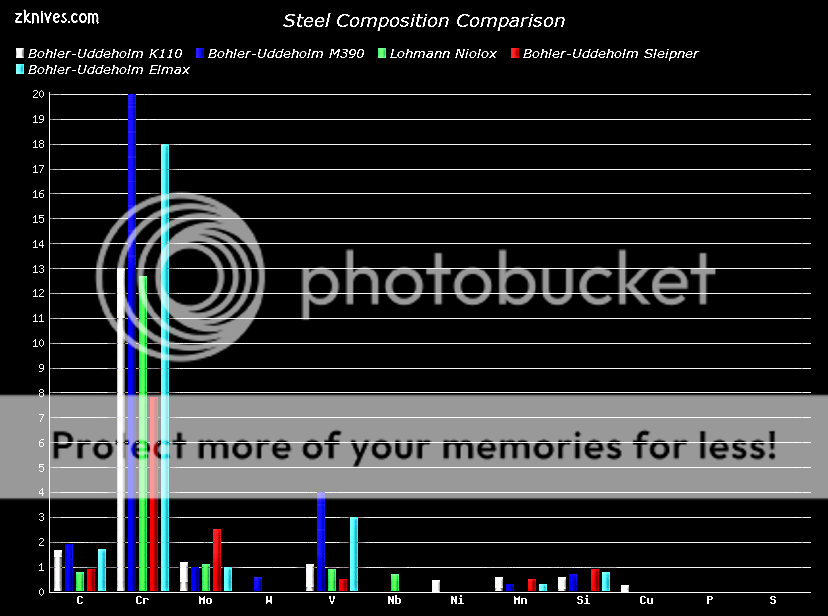

0 9c 0 9si 0 5mn 7 80cr 2 5mo 0 5v. 20 70 6 x 25 x 1000 mm. 48 00 13 x 30 x 100 mm. 30 00 6 x 30 x 100 mm.

Sleipner has improved toughness compared to d2 good wear and chipping resistance. 17 50 4 x 25 x 120 mm. 20 c 200 c 400 c density kg m3 7 680 7 620 modulus of elasticity mpa 205 000 190 000 180 000 coefficient of thermal expansion. Good wear resistance good chipping resistance high compressive strength high hardness 60 hrc after high tem perature tempering good through hardening properties good stability in hardening good resistance to tempering back good wedm properties good machinability and grindability good surface treatment properties.