Snap Lock Pittsburgh Lock Sheet Metal Fitting

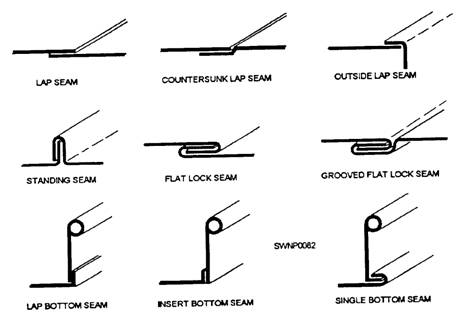

After one piece is inserted in the pocket the tail in hammered over to close the lock.

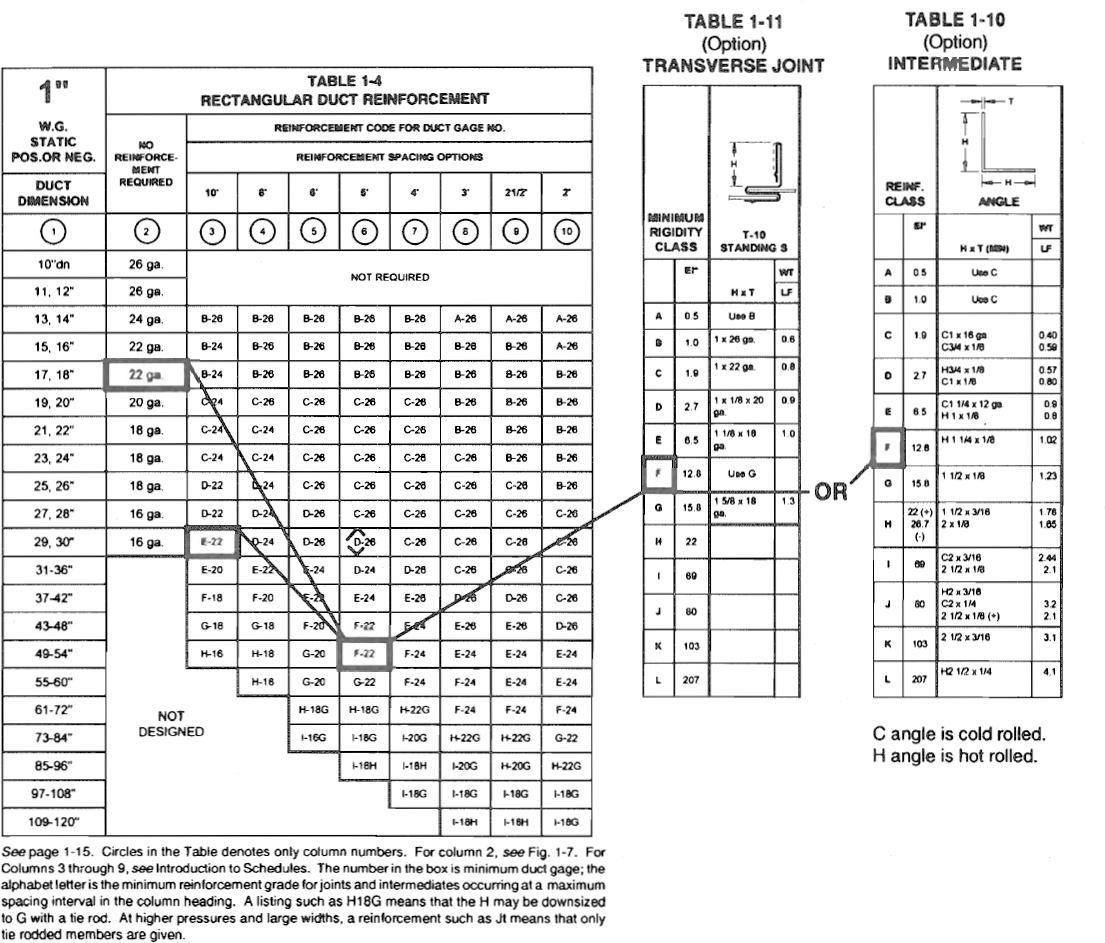

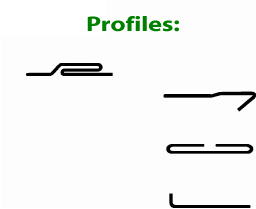

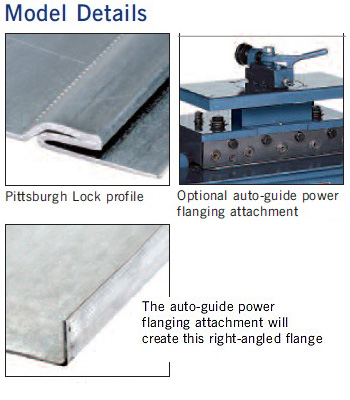

Snap lock pittsburgh lock sheet metal fitting. The radius button lock machine is the way to go. The pittsburgh lock seam fig. Even for radius fittings. Button snap lock and s clip need 9 sets of roller dies.

Machines used in high volume applications to form metal by running material through rollsets which progressively change the shape or profile. The male seam is a button the female seam is a lock and the two snap together for a flush corner. Figure 2 69 shows a cross section of the two pieces of metal to be joined and a cross section of the finished seam. Provide custom shapes and industry standard shapes such as pittsburgh snap lock button lock standing seam etc.

This seam is used as a lengthwise seam at comers of square and rectangular pipes and elbows as well as fittings and ducts. Originally formed in the brake or press brake today roll forming machines are used to form the pocket on one piece and the flange on the other piece. Snap lock button lock is for sure the best way to go. The button punch snap lock is used in the same way as the pittsburgh lock for joining comer sections of sheet metal.

Two piece duct showing the 5 16 pocket of the female pittsburgh and the 7 32 right angle flange of the male pittsburgh. A radius elbow consists of 2 cheeks these are the sides of the fitting and it s on the top part of this cheek that the right angle flange is turned at a 90º angle. Commonly used in the hvac industry roofing industry etc. Pittsburgh lock drive cleat and acme double seam are made on a machine with at least 5 sets of roller dies.

It s then hammered into the female seam of the pitts which is run on both longitudinal sides of the heel to complete the pitts lock on a radius elbow. When it comes to rectangular duct the pittsburgh lock is considered the longitudinal seam in commercial ductwork. These machines can form 0 4 to 1 2 mm sheet metal into female locks on the inboard and button punched right angle flanges on outboard rolls at speeds of 18m min and are available in seven and nine forming station machines. To form elbows use a manual or powered right angle flanger and slip rolls.

Its big advantage is that no additional hammer over operation is required with a direct result of less labor cost in assembly. You put the flange on the same way as the pittsburg cept you need a longer flange. Puts the flange and dimple in at the same time. If you need to feed lots of metal to a rollformer consider using an uncoiler.

-500x500.jpg)