Soft Seat Ball Valve Ptfe

50 316 powder combined with 50 ptfe.

Soft seat ball valve ptfe. Soft seats however aren t suitable for processing abrasive or dirty fluids. Soft seat options for ball valves. Almost all the industrial valves are metal seat and soft seat available. Flo tite offers metal seats in different classes of shut.

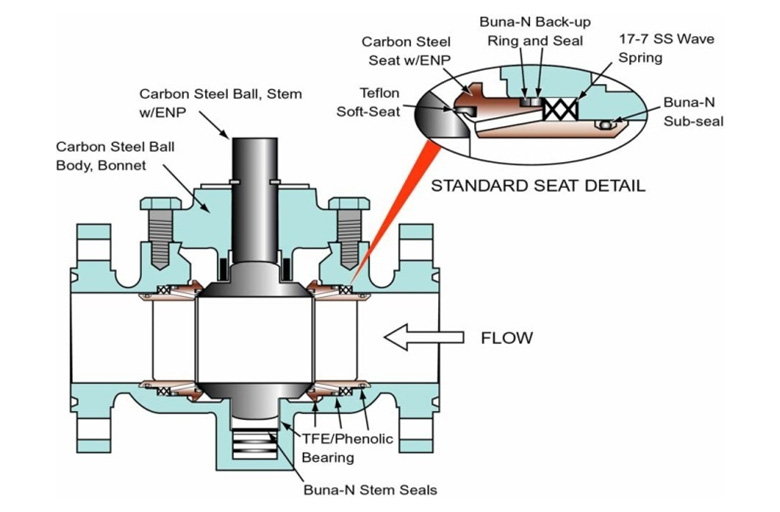

R ptfe r 15 glass reinforced ptfe suitable for temperature 50 f to 450 f chemical resistance is compatible to virgin ptfe with better wear factor. Apv offers metal seats in different classes of shut off including class i v and vi. Soft seats are generally made of thermoplastic materials like ptfe. Soft seated ball valves.

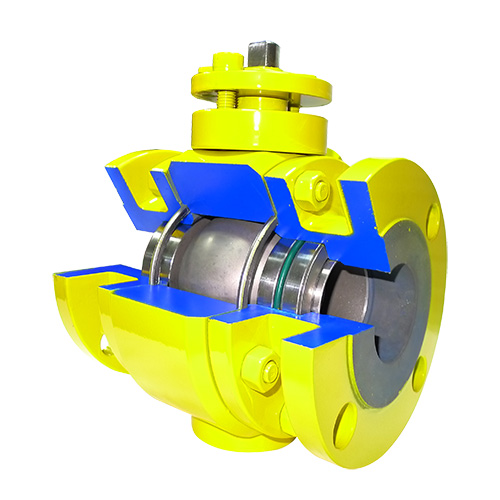

Both of them offers excellent sealing performance and have their unique and irreplaceable advantages and inevitably due to the shortcomings costs abrasion resistant performance working conditions of different materials metal seated valves and soft seated valves both. The soft seated ball valves are factory tested. They re great for applications where chemical compatibility is important and where the tightest seal is key. Soft seats are typically composed of thermoplastic components like ptfe.

Metallic 50 nylon special nylon seats are offered for higher pressure and lower temperature. Cavity filled seats are standard on our sanitary line of ball valves in both two and three way. However soft seats are not recommended for process fluids that are dirty or abrasive. The seat has high mechanical strength and abrasion resistance.

We provide valve seats manufactured from our af range of materials including ptfe and filled ptfe victrex peek and filled peek materials peek ht vespel pctfe nylon and acetal. Line contact between valve ball and seats resulting in smooth operation and tight shut off class. Soft seated ball valves. Please consult a t controls for seat material selection for your unique applications.

The ball seats are used in class jis 10k 20k asme class 150300 ductile iron stainless steel and carbon steel floating ball valves. Thrust washers and back up rings. These valves are appropriate for applications in which chemical compatibility is crucial and in situations where having the tightest seal is important. These parameters are guidelines and customers are responsible for materials of construction being compatible with their valve application.

Soft seats can break down in these conditions. The most common fluoropolymer application is in process valves. C f ptfe carbon fiber filled polytetrafluoroethylene resin this ball seat is made of ptfe reinforced with carbon.